Description

| project | Unit | Parameters | project | Unit | Parameters |

| Maximum rotation diameter of the bed | mm | φ650 | Z-axis travel | mm | 320 |

| Maximum diameter of processed disk parts | mm | φ380 | Y-axis travel | mm | ±45 |

| Maximum processing length | mm | 300 | X/Z axis movement speed | m/min | 20/20 |

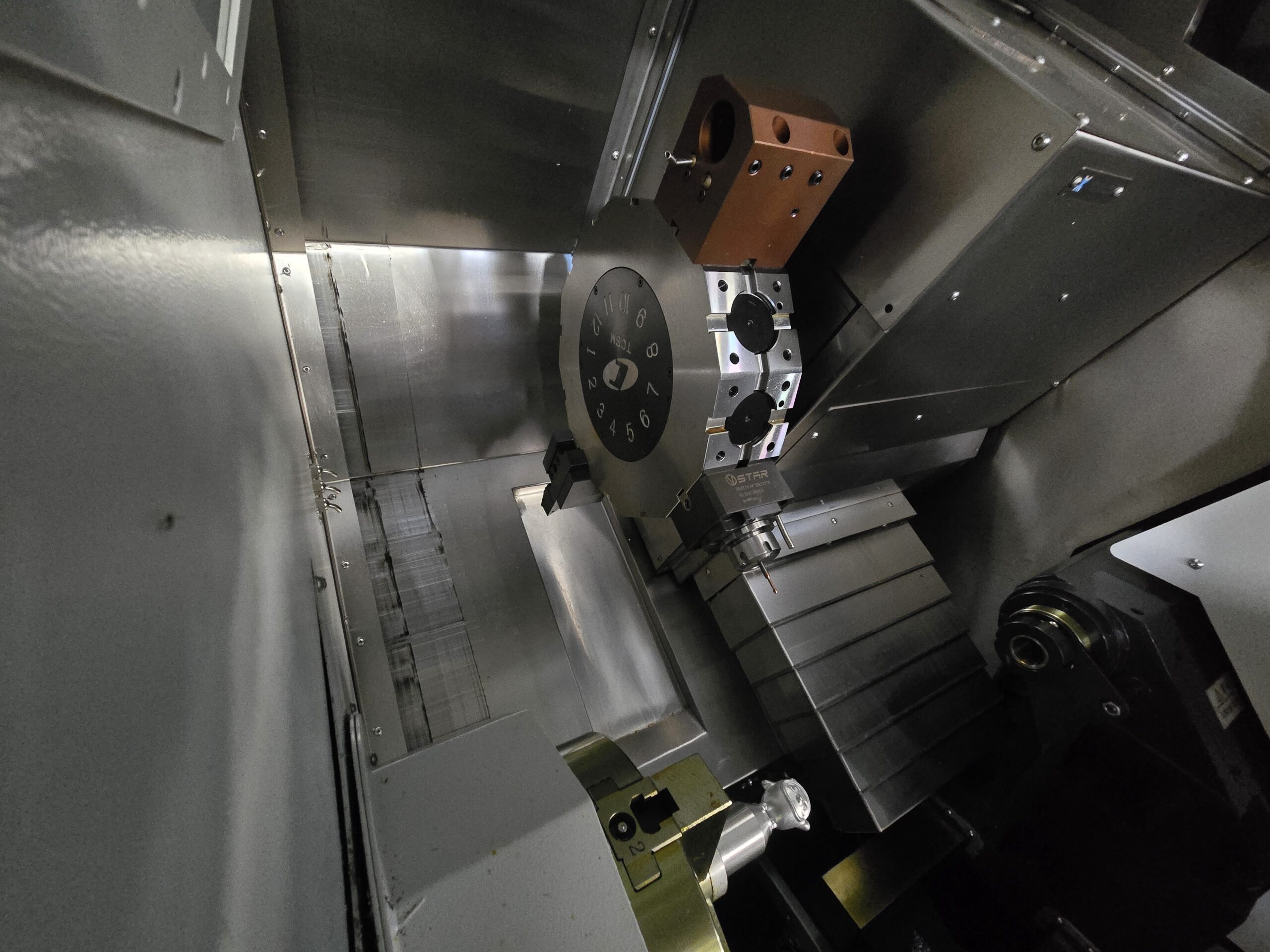

| Spindle through hole diameter | mm | φ66 | Tool holder form | 12-station Y-axis powered tool turret | |

| Diameter of bar through hole processed in spindle | mm | φ50 | Tool specifications/boring tool diameter | mm | 25X25/φ40 |

| Spindle motor power | kw | 22.75 | Tailstock sleeve taper | Mohs No. 4 | |

| Spindle maximum speed | rpm | 4300 | Tailstock sleeve diameter | mm | 80 |

| Spindle end specifications | N/A | A2-6 | Several bed sizes | mm | 2380X1800X1900 |

| X-axis travel | mm | 230 | Machine weight | kg | 3600 |

| Standard | Optional |

| Control system: FANUC, Mitsubishi, Siemens | Chip conveyor |

| Servo main motor | Grating ruler |

| 8-inch hollow three-jaw chuck | |

| 8 inch hollow rotationoil cylinder | |

| Roller linear guide | |

| 12-station Y-axis powered tool turret | |

| Hydraulic brake | |

| cooling pump | |

| Automatic lubrication pump | |

| Cabinet air conditioner |

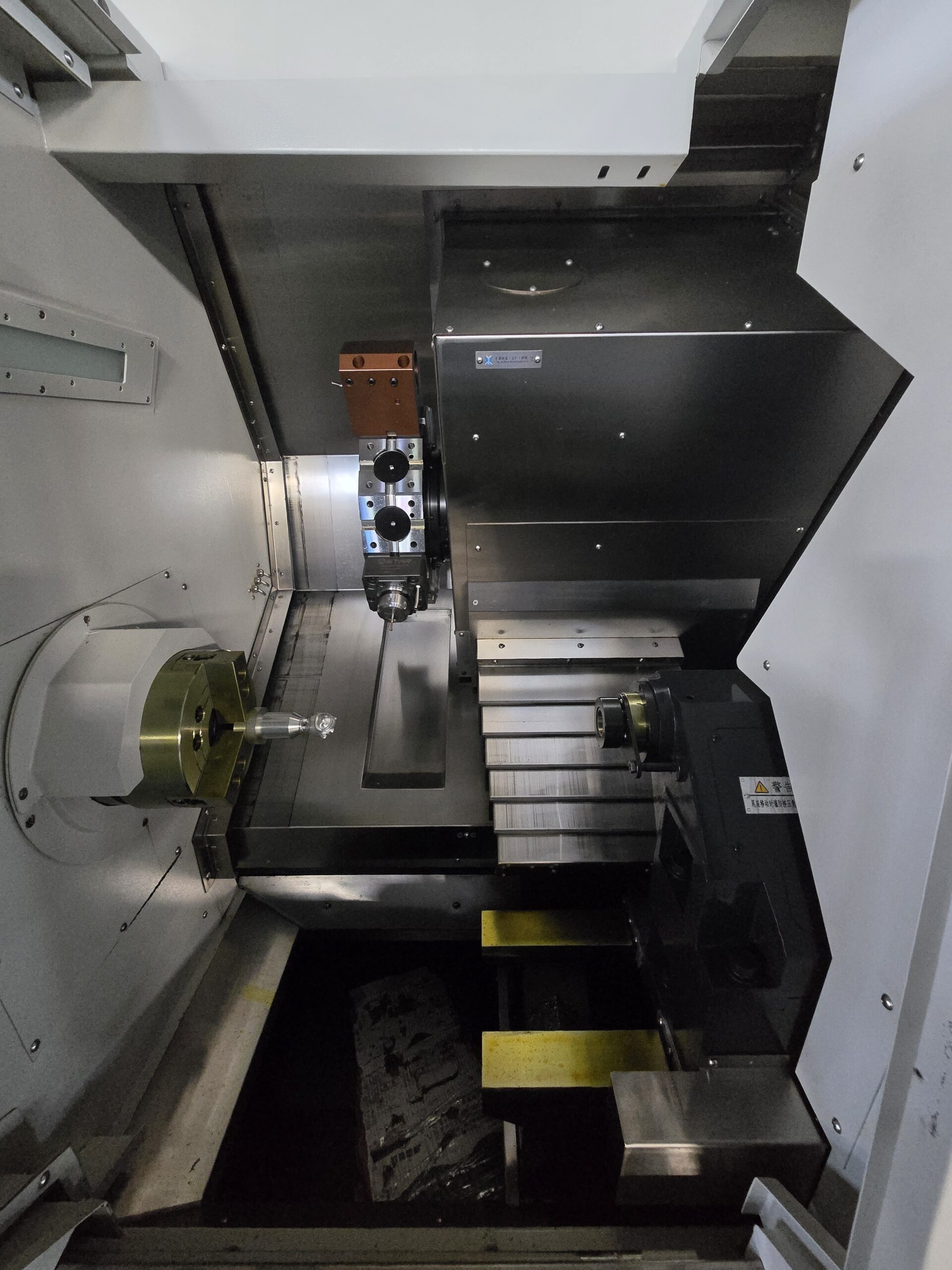

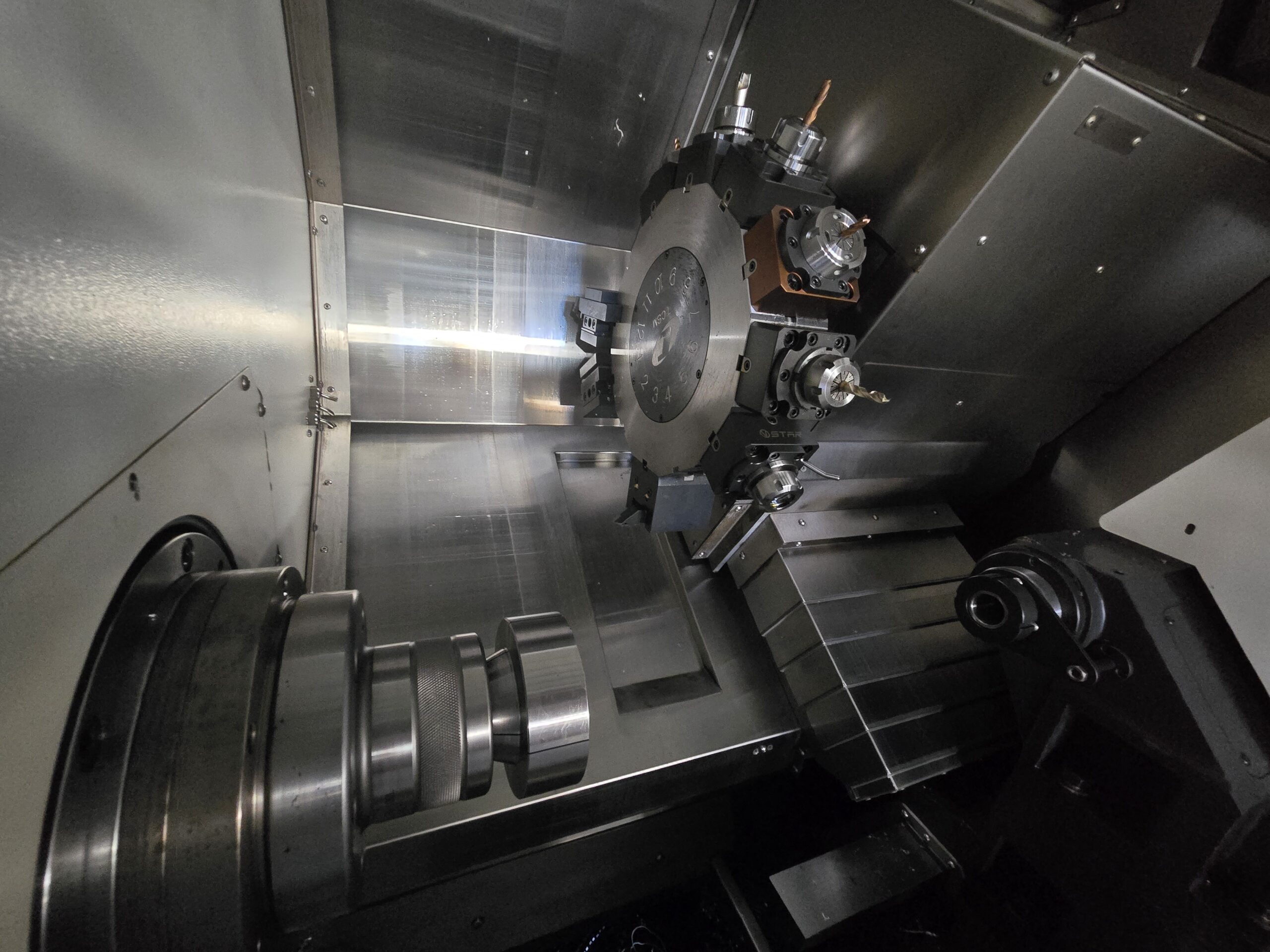

The H06Y turn-milling compound machine tool adopts HT300 labeled castings cast in one piece, following the design philosophy of finite element analysis technology. The structure and layout are rational, and the castings undergo natural aging and secondary heat treatment to release stress, ensuring processing precision and stability.

Key Features:

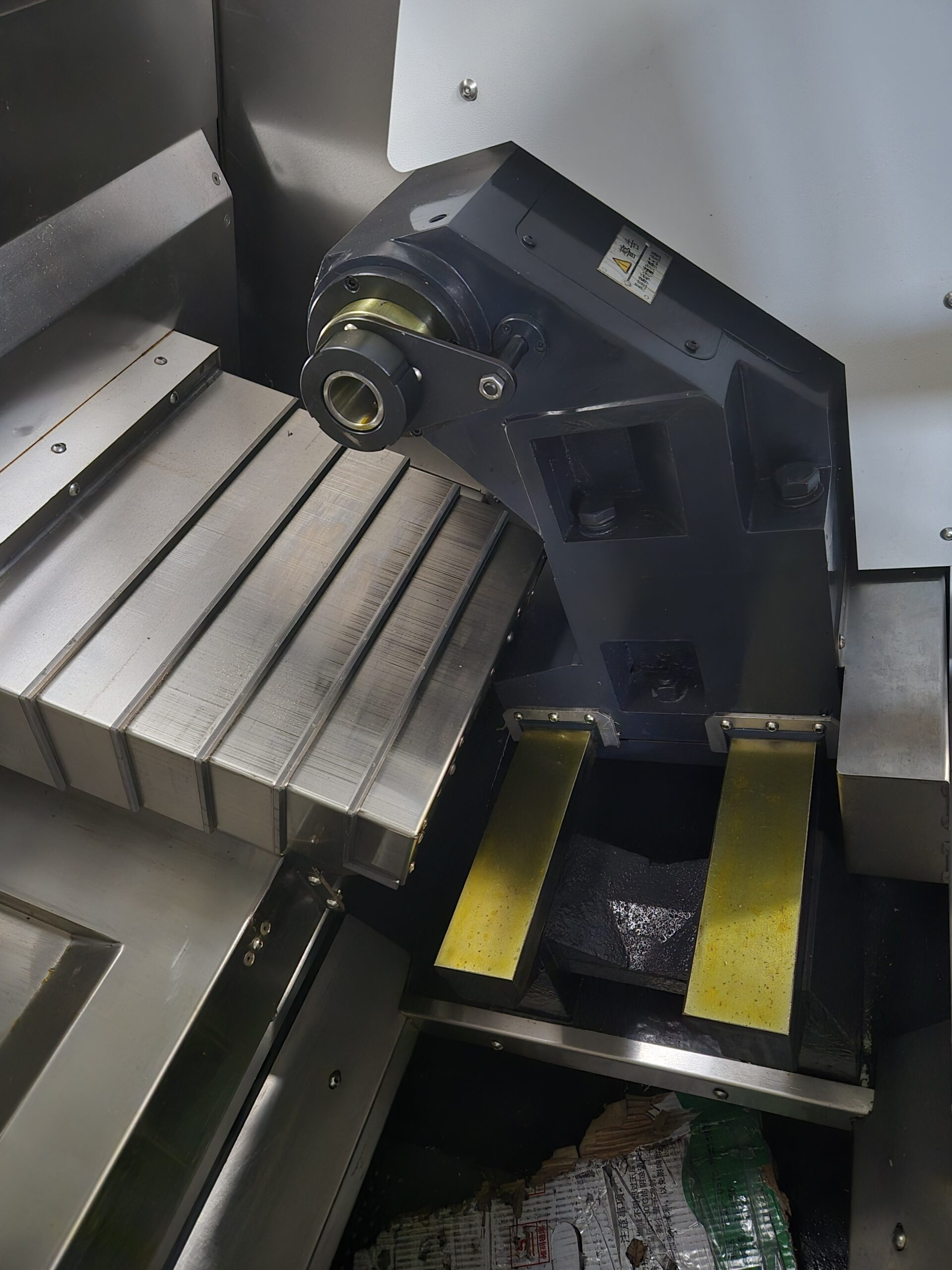

X/Z axis utilizes roller linear guides with a large span, meeting stringent requirements for stability, rigidity, and precision.

Precision electric spindle with imported bearings undergoes multi-layer testing for stability and accuracy post-assembly.

Equipped with a 12-position power turret with Y-axis movement, allowing quick tool changes with high precision. The power turret moves on a column support plate at 90° vertically, facilitating drilling, milling, tapping, and other processes. It can complete the entire complex product processing in a single operation, ensuring precision and efficiency without the need for a second operation.

X/Z/Y axis lead screws use precision imported ball screws with pre-stretching technology, minimizing thermal deformation and ensuring high transmission accuracy.

Lead screws are supported by imported bearings and use high-precision locking nuts to effectively control the precision of long-term machine tool processing.