Claire Dubois

Directrice RH, Alpinea

“Grâce à Nexus Learning, nous avons augmenté de 40 % le taux de complétion des formations internes.”

★★★★★

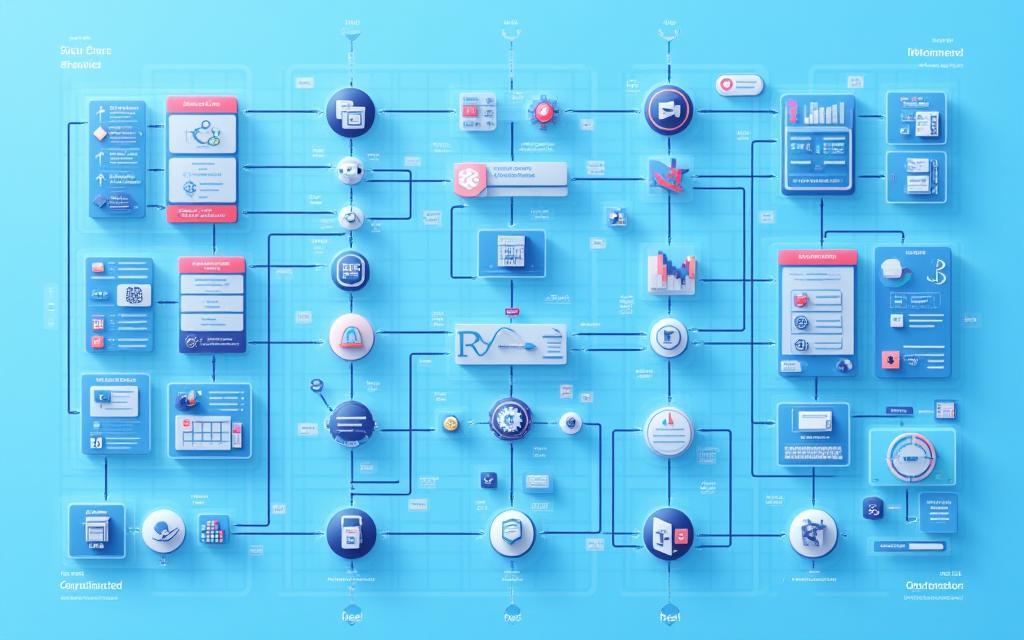

Plateformes d’apprentissage, domotique, voyages et bien-être réunis dans un seul écosystème.

Fondée en 2015 dans le quartier historique des Terreaux à Lyon, TechÉdu Nexus développe des solutions logicielles pensées pour enrichir la vie quotidienne : apprentissage continu, bien-être personnalisé, voyages responsables et habitats intelligents.

Notre mission est simple : démocratiser des technologies sécurisées et durables qui apportent une réelle valeur ajoutée aux utilisateurs et à la planète. Chaque ligne de code est conçue pour être performante, inclusive et éco-optimisée.

Plateforme e-learning SCORM & xAPI complète avec analytics en temps réel.

Suivi fitness multidevice synchronisé avec Apple Health & Google Fit.

Gestion de voyages d’entreprise avec optimisation carbone.

Domotique intelligente contrôlable par voix & mobile.

Accompagnement stratégique pour établissements et formateurs.

Énergie 100 % renouvelable, refroidissement liquide, PUE < 1.2.

Code minifié, éco-design numérique, réduction des requêtes HTTP.

1 % du chiffre d’affaires reversé à des programmes d’éducation gratuite.

d’émissions carbone (2023 vs 2021)

de composants recyclables dans nos devices

Claire Dubois

Directrice RH, Alpinea

“Grâce à Nexus Learning, nous avons augmenté de 40 % le taux de complétion des formations internes.”

★★★★★

Marc Leroy

Propriétaire, Résidence Verte

“La solution domotique Nexus Home a réduit notre consommation d’énergie de 18 %.”

★★★★☆

Sonia Benarous

Travel Manager, Voyagenix

“Un outil de gestion de voyages qui tient réellement ses promesses environnementales.”

★★★★★

Julien Caradec

CTO, EcoLogi

“L’API Nexus Fitness nous a permis d’intégrer en deux jours un suivi santé dans notre propre application.”

★★★★★

Béatrice Nguyen

Formatrice indépendante

“La gamification de Nexus Learning a doublé l’engagement de mes étudiants adultes !”

★★★★☆

Adresse : 72 Rue de la Barre, Étage 1, 69001 Lyon, France

Téléphone : +33 4 72 12 34 56

Email : info@

Horaires : Lun–Ven : 9h00 – 18h00