Description

| project | Unit | Parameters | project | Unit | Parameters |

| Maximum rotation diameter of the bed | mm | φ550 | Tailstock travel | mm | 0-250 |

| Maximum diameter of processed disk parts | mm | φ430 | X/Z axis movement speed | m/min | 20/20 |

| Maximum processing length | mm | 350 | Tool holder form | mm | 12-station servo turret |

| Spindle motor power | kw | 7.5 | Tool specifications/boring tool diameter | mm | 25X25/φ32 |

| Spindle maximum speed | rpm | 4000 | Tailstock sleeve taper | Mohs No. 4 | |

| Spindle end specifications | N/A | A2-6 | Tailstock sleeve diameter | mm | 80 |

| Spindle through hole diameter | mm | φ56 | Tailstock sleeve travel | mm | 80 |

| X-axis travel | mm | 230 | Several bed sizes | mm | 2380X1800X1690 |

| Z-axis travel | mm | 360 | Machine weight | kg | 3200 |

| Standard | Optional |

| Control system: FANUC, Mitsubishi, Siemens | Chip conveyor |

| Servo main motor | Grating ruler |

| Mechanical spindle unit | |

| Roller linear guide | |

| Mohs No. 4 tailstock | |

| 12-station servo turret | |

| 6 inch hollow rotationoil cylinder | |

| heat exchanger | |

| cooling pump | |

| Automatic lubrication pump |

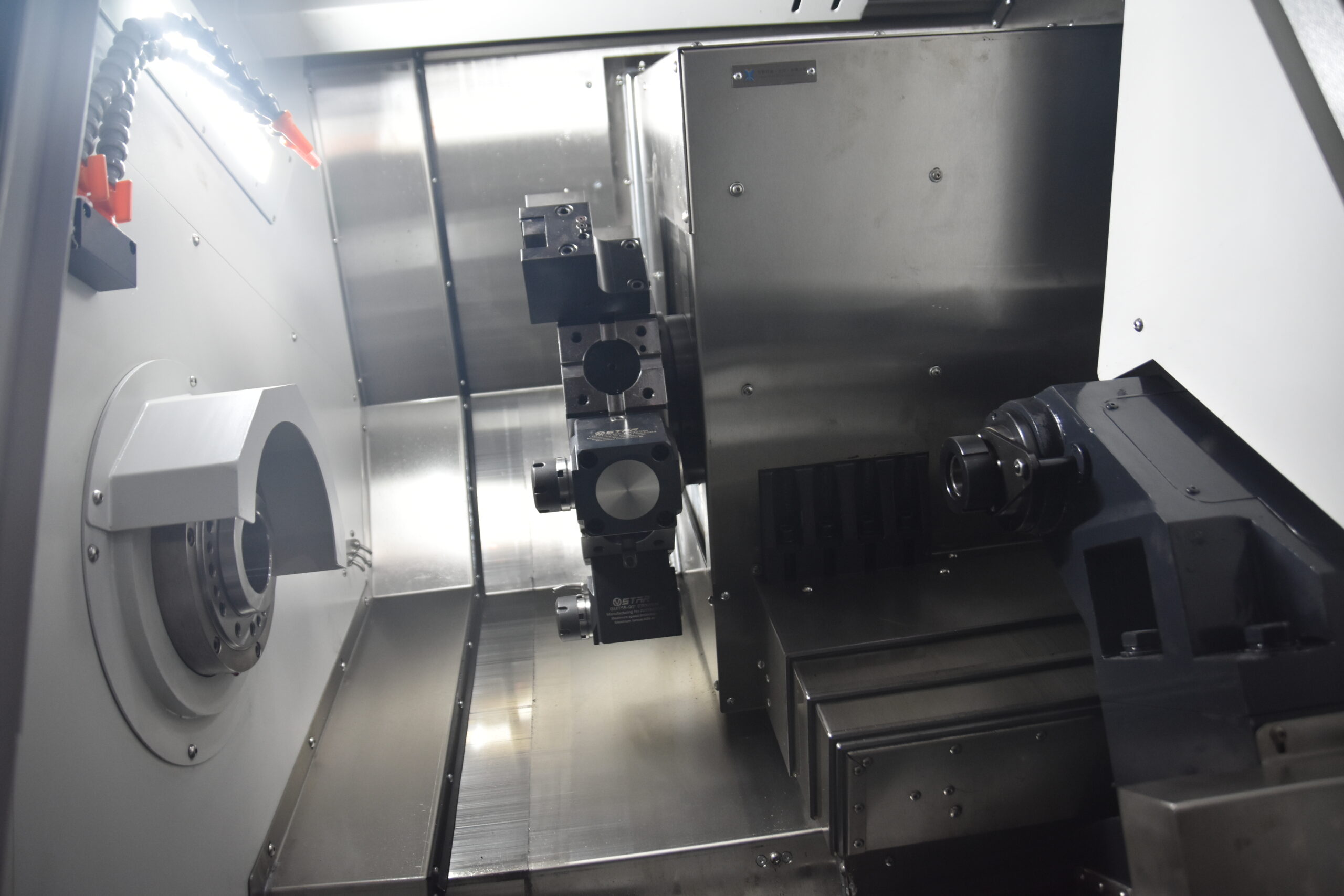

The PML-H06 machine tool also features a one-piece cast base and bed, with an inclined bed for ease of processing and chip removal. The design incorporates finite element analysis, ensuring a rational structure and excellent layout. Castings undergo natural aging and secondary tempering for long-term stability[1].

The X and Z directions utilize roller linear guides, with two large-span, stable, and rigid linear guides effectively maintaining machining accuracy.

It features a precision electric spindle equipped with SFK bearings, ensuring accuracy, rigidity, and speed.

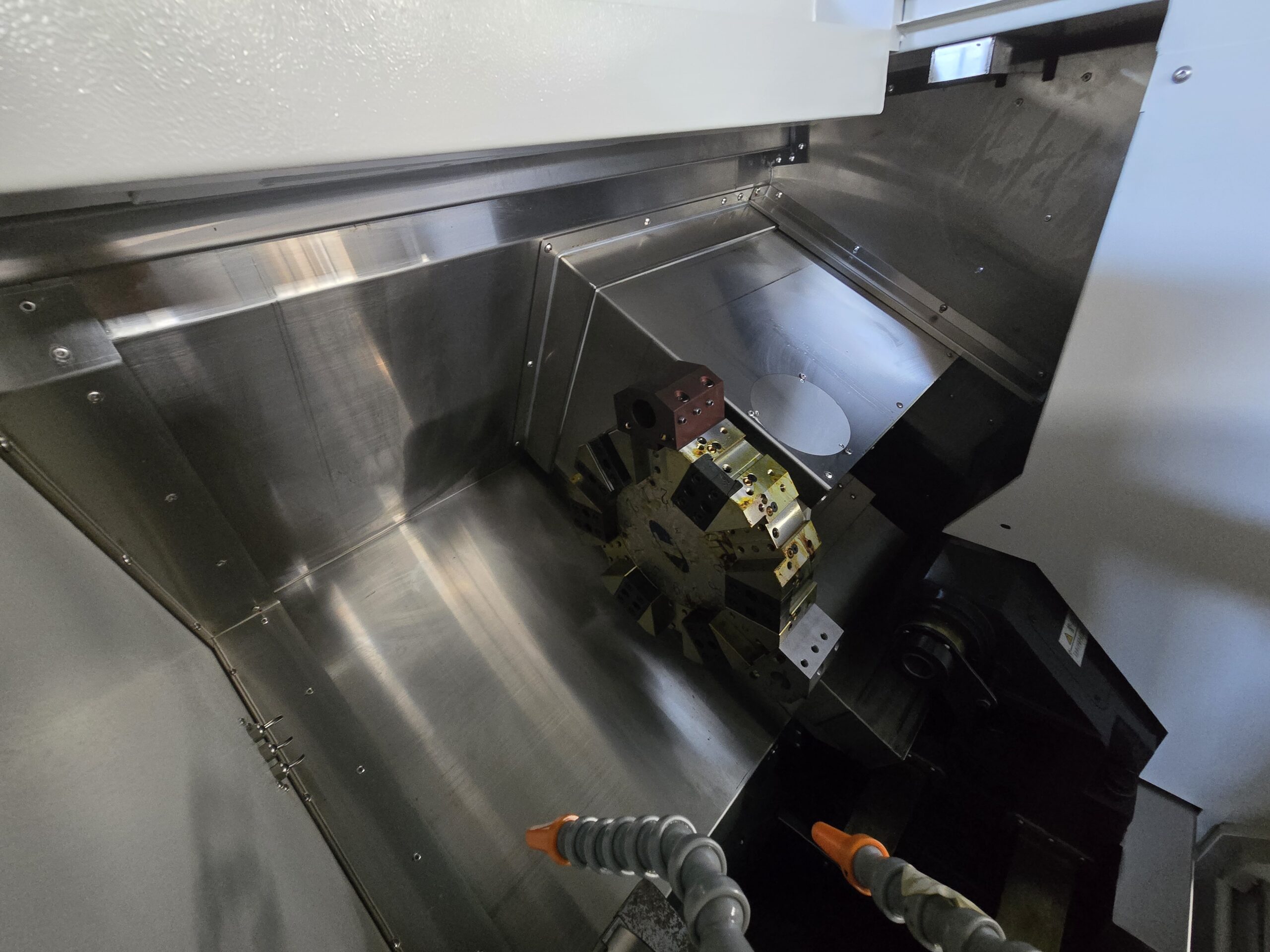

The PML-H06 adopts a 12-position servo turret, offering bidirectional positioning, quick tool change, and accurate positioning.

The 2-axis screw adopts imported precision ball screws combined with a pre-stretching process, minimizing thermal deformation and ensuring high transmission accuracy.

Screw support utilizes SFK bearings, and the locking nut employs high-precision locking nuts, following strict assembly sequences to ensure machining accuracy.

The PML-H06 is designed with both side and rear chip removal modes, providing users with the flexibility to choose according to their needs.