Description

| model |

unit |

VMC1275 |

VMC1370 |

VMC1380 |

| Casting mark |

|

HT300+ |

HT300+ |

HT300+ |

| Processing table size |

mm |

1300X700 |

1400X700 |

1400X800 |

| Processing table load-bearing |

kgs |

900 |

1000 |

1000 |

| X/Y/Z axis travel |

mm |

1200X750X600 |

1300X700X700 |

1300X800X700 |

| T-slot size |

mm |

7X18X100 |

5X18X110 |

7X18X110 |

| Spindle taper |

|

BT40/BT50 |

BT40/BT50 |

BT40/BT50 |

| Spindle power |

kw |

11kw/15kw |

15kw/18.5kw |

15kw/18.5kw |

| Spindle transmission mode |

|

Belt/direct connection/electric spindle |

Belt/direct connection/gear box |

Belt/direct connection/gear box |

| Spindle speed |

rpm |

8000-20000 |

6000-15000 |

6000-15000 |

| Three-axis track design |

|

threeaxisrollcolumn/Two linear guides and one hard rail |

threeaxisrollcolumn/Two linear guides and one hard rail |

threeaxisrollcolumn/Two linear guides and one hard rail |

| Rapid feed X/Y/Z |

m/min |

36/36/36 |

24/24/24 |

30/30/30 |

| Cutting feed X/Y/Z |

mm/min |

1-10000 |

1-10000 |

1-10000 |

| Three axis track width |

mm |

45/55/45 |

45/45/45 |

50/50/50 |

| Three-axis guide rail brand |

|

PMI/HIWIN/THK |

PMI/HIWIN/THK |

PMI/HIWIN/THK |

| Guide rail bearing brand |

|

NACHI |

NACHI |

NACHI |

| positioning accuracy |

mm |

±0.008 |

±0.008 |

±0.008 |

| repeatpositioning accuracy |

mm |

±0.006 |

±0.006 |

±0.006 |

| air pressure requirement |

kgs |

6 |

6 |

6 |

| Machine weight |

kgs |

≈7500 |

≈10500 |

≈11500 |

| Machining center size |

mm |

3150X2430X2400 |

3200X2540X2600 |

3256X2714X3610 |

| model |

unit |

VMC1580 |

VMC1890 |

| Casting mark |

|

HT300+ |

HT300+ |

| Processing table size |

mm |

1600X800 |

2000X900 |

| Processing table load-bearing |

kgs |

1100 |

2000 |

| X/Y/Z axis travel |

mm |

1500X800X700 |

1800X900X800 |

| T-slot size |

mm |

7X22X110 |

7X22X125 |

| Spindle taper |

|

BT40/BT50 |

BT50 |

| Spindle power |

kw |

15kw/18.5kw |

15kw/18.5kw |

| Spindle transmission mode |

|

Belt/direct connection/gear box |

Belt/Gearbox |

| Spindle speed |

rpm |

6000-15000 |

6000-8000 |

| Three-axis track design |

|

threeaxisrollcolumn/Two linear guides and one hard rail |

threeaxisrollcolumn/Y axis four tracks |

| Rapid feed X/Y/Z |

m/min |

30/30/30 |

30/30/30 |

| Cutting feed X/Y/Z |

mm/min |

1-10000 |

1-10000 |

| Three axis track width |

mm |

55/45/55 |

55/55/55 |

| Three-axis guide rail brand |

|

PMI/HIWIN/THK |

PMI/HIWIN/THK |

| Guide rail bearing brand |

|

NACHI |

NACHI |

| positioning accuracy |

mm |

±0.008 |

±0.01 |

| repeatpositioning accuracy |

mm |

±0.006 |

±0.008 |

| air pressure requirement |

kgs |

6 |

6 |

| Machine weight |

kgs |

≈12800 |

≈14500 |

| Machining center size |

mm |

3850X2720X3610 |

4800X3100X3300 |

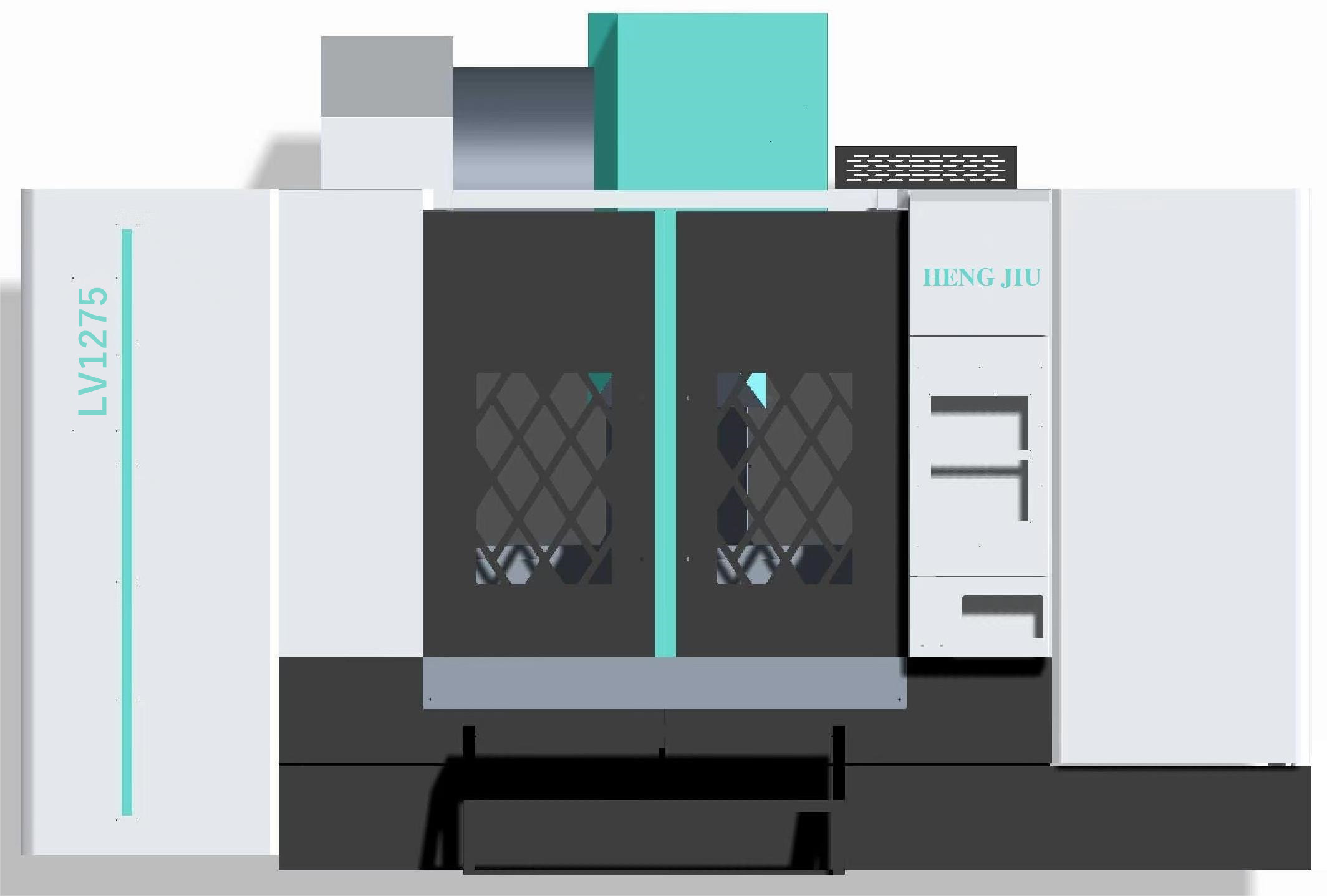

The castings of Hengjiu Intelligent Vertical Machining Centers are made of HT-300 grade material. Utilizing the MiHanna process for natural aging, the castings undergo segmented rough machining and precision machining to ensure long-term accuracy in later production. The design incorporates the Beidler technology with a large-span inverted structure, and the internal cavity is reinforced with a ribbed structure to enhance the overall column stiffness.

Manufacturing an efficient machining center is a meticulous process, emphasizing detail optimization, robust material selection, and functional component choices. This includes adhering to standardized and systematic assembly processes. We are confident in our commitment to pursuing excellence.