Description

| project | Unit | Parameters | project | Unit | Parameters |

| Maximum workpiece rotation diameter on the bed | mm | φ360 | Spindle maximum speed | rpm | 3000 |

| Maximum rotation diameter of pallet | mm | φ90 | X/Z axis travel | mm | 350/500 |

| Maximum processing length | mm | 200 | X/Z axis rapid movement | m/min | 20/20 |

| main motor power | kw | 4 | Machine tool dimensions | mm | 2005X1680X1700 |

| Spindle end specifications | N/A | A2-5 | Machine tool net weight | kg | 1875 |

| Spindle through hole diameter | mm | φ50 |

| Standard | Optional |

| Control system: FANUC, Mitsubishi, Siemens | Chip conveyor |

| Servo main motor | Grating ruler |

| Mechanical spindle unit | |

| 6 inch hollow rotationoil cylinder | |

| Ball linear guide | |

| Chuck seat | |

| Spring collet | |

| cooling pump | |

| Automatic lubrication pump |

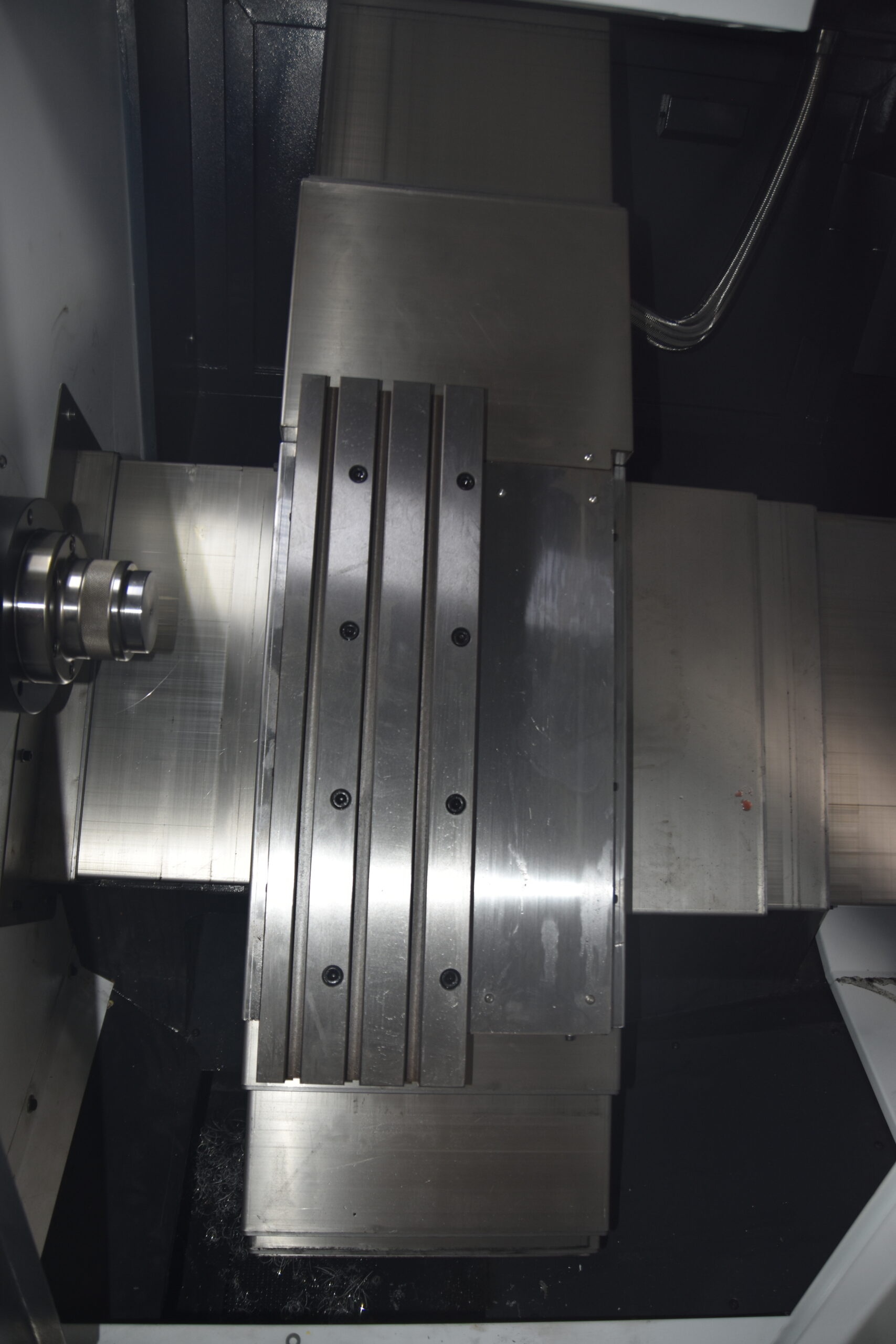

The HJ35 adopts a modular design with a compact overall structure. The bed is made of wear-resistant iron casting, providing excellent rigidity and high load-bearing capacity, resulting in high precision and smooth operation. The 45° inclined bed is advantageous for workpiece installation and removal and offers good chip removal performance.

The machine tool is driven by servo motors for the main spindle, capable of meeting various machining speed requirements. Both the X and Z axes utilize linear guides, ensuring precise positioning and stable operation.

The HJ35 exhibits high adaptability for machining and can efficiently handle parts of various shapes, maintaining a high level of machining stability. Upgraded sheet metal protection enhances the HJ30’s noise reduction, water resistance, rust prevention, and chip protection capabilities.”